“Hockey is a progressive sport, and this turf helps Paris 2024 meet its environmental goals and puts hockey at the forefront of sustainability.”

Hockey goes full circle

From natural grass to carbon zero hockey turf.

Poligras Paris GT zero, developed for the Paris 2024 Olympics is the world’s first and only carbon zero hockey turf and has also been FIH Innovation-certified for dry hockey.

80% biobased material (sugarcane)

Made with green energy

Turf Glide technology means unique ‘play wet / play dry’ crossover performance

Available globally

Using sugarcane as a bio-raw material means the Poligras Paris GT zero turf saves 73 tonnes of CO₂ compared to a conventional turf. The carbon footprint of the turf has been certified as a climate-neutral by Berlin-based DAkkS accredited consulting company GUTcert.

The Paris turf features a new and proprietary friction-reducing technology called Turf Glide, which reduces friction and abrasion, allowing the turf to meet the FIH Innovation standards for dry hockey.

Turf Glide not only means that when dry, the Paris turf plays better-than-sand, but also that less water is required to lubricate the turf for elite hockey. In many locations the atmospheric moisture, such as light rain or dew on a cool night, will be enough to transform the turf to Olympic level performance. This gives facilities the flexibility to do a dry installation (i.e. without an irrigation system) and benefit from an upgrade when there is moisture in the air.

A hit around the world

With one year until the Olympics in Paris, Poligras Paris GT zero has been chosen by venues in Australia, England, Germany, France, India, Oman, Namibia, New Zealand, Northern Ireland, South Africa and USA, including for the Asian Champions Trophy in Chennai.

“Our Poligras Paris GT zero turf plays very well when dry - significantly better than a sand-dressed field.”

Play On. Hockey’s First Carbon Zero Water Zero Turf.

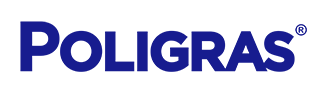

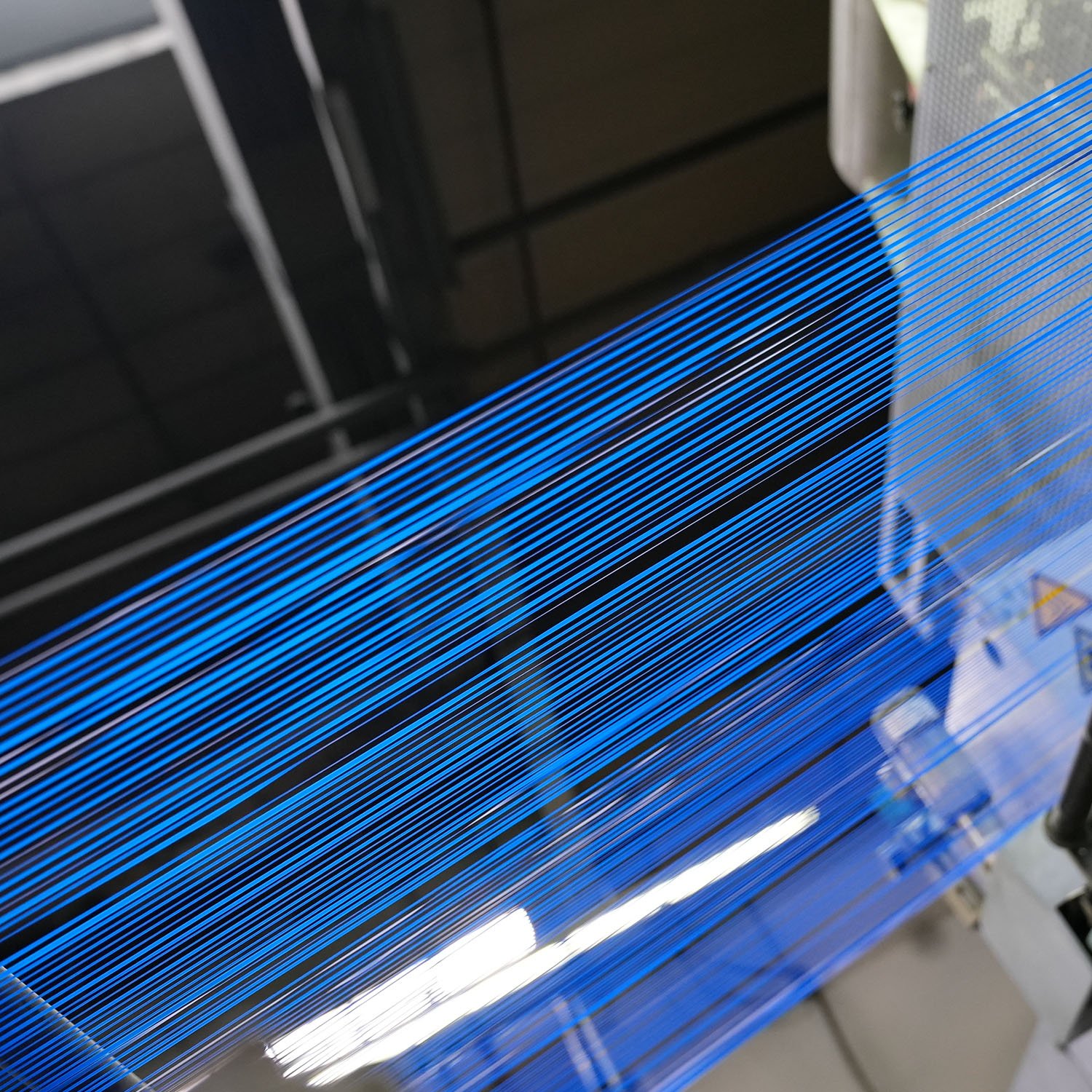

Poligras Paris GT zero is our next Green Technology (GT) advance. Made with 80% sugarcane it replaces fossil fuel-based polyethylene with bio-based polyethylene in the manufacture of the turf fiber.

This Green Technology was developed for the Tokyo Olympic turf (60% sugarcane). Our Poligras Tokyo GT turf, with over 60 installations, demonstrated that the hockey community wants a more sustainable future for their sport.

Poligras Paris GT zero also features a new proprietary friction-reducing technology called Turf Glide, which reduces friction and abrasion, allowing the turf to meet the FIH Innovation standards for dry hockey.

Turf Glide not only means that when dry, the Paris turf plays better-than-sand, but also that less water is required to lubricate the turf for elite hockey.

Poligras Paris GT zero is affordable and will become a long-term Olympic quality asset for clubs and hockey around the world:

Play wet / play dry

Grow club pride and excitement

Improve the quality of play, from juniors to seniors

Attract better players to your club

Host events, tournaments and elite training

“Even on the dry turf we can train almost equally, which gives us more flexibility and at the same time a consistently higher level of training.”

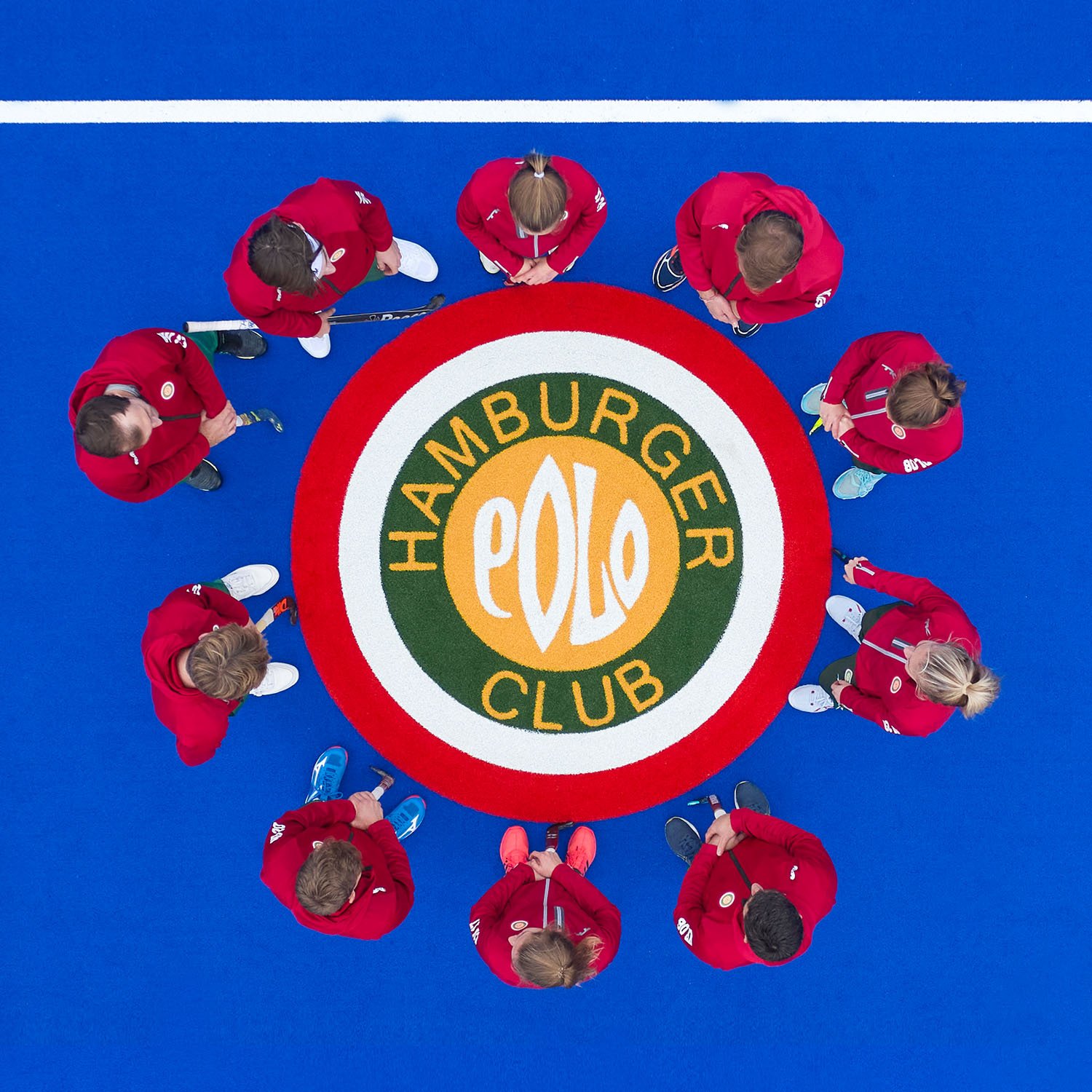

First to Play Hockey Zero

Hamburger Polo Club, Hamburg, Germany

The first Poligras Paris GT zero turf was installed at the historic Hamburger Polo Club, Germany by Polytan in October, 2022. We are delighted to have our revolutionary turf installed at such a historic and important hockey club.

The first Hockey Zero game was a Bundesliga match between Hamburger Polo Club and Rot-Weiss Köln on 31 March, 2023. This was not only the first Hockey Zero match, but was the first match for the Hamburger Polo on their own grounds. It was a great occasion with a big crowd cheering on the home side to a 3-1 victory against a team packed with German international stars.

“It’s a big advantage for our international players to train on the pitch”

“Future Olympic stars are born at the grassroots and we transform clubs and schools into ‘fields of dreams’ with our Olympic quality surfaces.”

The first Poligras Paris GT zero turf has arrived in New Zealand

Lloyd Elsmore Park, the home of Auckland Hockey, now features the next generation Olympic turf in a move that supports both their environmental and player performance goals. They are regularly using the turf try and find that atmospheric moisture is enough to create a fast and fluid surface. Find out more about what the new turf means for New Zealand Hockey and how it could transform your facility.

Hockey Zero helps the sport play on

-

Our Paris turf technology uses I’m Green™ polyethylene, a revolutionary bioplastic from Braskem.

Plastics are typically made from fossil fuels, however I’m Green™ polyethylene is a plastic obtained from ethanol derived from sugar cane.

In the production of I’m Green™ polyethylene, the first two sugarcane pressings are used for sugar. The third pressing (not good enough for sugar production) is used as the raw material for bio-polyethylene production.

To achieve CO2-neutral energy production, the bagasse, a byproduct of the sugar cane pressing, is used in the bio-power plant to generate energy and steam (heat).

To further close the loop, the ashes produced during the incineration of the bagasse are used as organic fertiliser on the sugar cane fields.

The carbon footprint of the Poligras Paris GT zero turf has been certified as a climate-neutral product by Berlin-based DAkkS accredited consulting company GUTcert.

-

Each Olympics since Sydney has seen a reduction in the amount of water required for optimum play. For example, the Tokyo Olympic turfs required 39% less water than the turfs at Rio 2016

The Paris turf continues this tradition, it features a new and proprietary friction-reducing technology called Turf Glide, which reduces friction and abrasion, allowing the turf to meet the FIH Innovation standards for dry hockey.

Turf Glide not only means that when dry, the Paris turf plays better-than-sand, but also that less water is required to lubricate the turf for elite hockey.

Poligras Paris GT zero only requires 1mm of water across the surface to achieve Olympic level performance and meet FIH skin friction requirements.

For many locations the atmospheric moisture, such as light rain or dew on a cool night, will be enough to transform the turf to Olympic level performance.

-

The lifetime of the product has the most impact on climate and the environment.

Poligras Paris GT zero, like all our hockey turfs, is therefore designed, manufactured, and certified to be extremely durable and maintain performance over many years of intensive use.

Strong protection against UV radiation and degradation is particularly important, and our fibers are designed to withstand hockey’s harshest climates like Australia and India.

Recycling is an essential, but until recently, an underestimated part of the lifecycle of a turf. Sport Group as the world’s largest business in the industry is investing in new recycling technologies and partnerships globally. Our new FormaTurf factory in Germany is a unique and revolutionary solution that recycles all the components of an artificial turf system and gives them a second life.

And remember, regular turf cleaning and maintenance will extend the life of your turf - and that is great for the environment.

“We invested another two years of R&D to increase the sugarcane usage to 80% and create a carbon zero hockey turf for Paris”

Photo: Hamburger Polo Club, Poligras Paris GT zero

Carbon Zero Turf - available globally

Poligras is Sport Group’s global hockey turf brand, and Poligras Paris GT zero is available from Sport Group companies around the world - Polytan in EMEA and Asia Pacific, and AstroTurf in the USA and the Americas.

Poligras has hockey’s largest turf portfolio, covering entry level hockey facilities to Olympic competition.

Poligras is trusted & chosen by players, schools, clubs and major venues worldwide:

8 Olympic Games

12 World Cups (including 2018, 2022, 2023, 2026)

25% of all FIH certified turfs

10 of the 14 Tokyo 2020 Olympic Qualifiers

70% of FIH Pro League matches

From Amsterdam to Auckland, from London to Lahore, Polytan and AstroTurf can help with every aspect of your hockey turf project, including design, installation, and maintenance.

Together these brands have been supporting hockey since 1976. We have hockey representatives in all markets and have the biggest installation network in the world. Our teams install hockey turfs for the Olympic Games, World Cups, Asian Games, Commonwealth Games, major stadiums, clubs and schools around the world. We can help bring your hockey project to life.

“Hockey’s my game - I still play, and I am proud that we make hockey around the world”

With Poligras you not only get hockey’s overwhelmingly #1 turf, but you get the in-depth knowledge of local experts who can help make your hockey turf a long-lasting, sustainable success.

46 years of hockey-first innovation

Our carbon zero hockey turf is the latest of our hockey innovations that have helped shape the game. Our hockey innovations include:

1976 First turf (Montreal)

2000 First colored turf (Sydney)

2003 First polyethylene turfs (softer, less bounce)

2012 First blue turf (London)

2014 First texturized turf (multi-directional play)

2016 30% less water (Rio)

2019 First Big Stadium Hockey (London)

2020 First sugar cane turf (Tokyo)

2020 39% less water (Tokyo)

2022 First Hockey 5s (Lausanne)

2022 First carbon zero turf (Paris)

1976 First turf (Montreal) 2000 First colored turf (Sydney) 2003 First polyethylene turfs (softer, less bounce) 2012 First blue turf (London) 2014 First texturized turf (multi-directional play) 2016 30% less water (Rio) 2019 First Big Stadium Hockey (London) 2020 First sugar cane turf (Tokyo) 2020 39% less water (Tokyo) 2022 First Hockey 5s (Lausanne) 2022 First carbon zero turf (Paris)

We love hockey, we have been hockey’s best partner since 1976, and today our commitment runs deep in the sport.

Sport Group, Polytan and AstroTurf commit to the long-term health of the game, we are partners with the FIH (International Hockey Association) and Asian Hockey Federation, as well as many hockey organizations around the world:

Read more about our innovations and commitment to the game.

More international teams choose Poligras

Not all hockey turfs are created equal. They may look similar, but the feel and the performance (especially speed) are different. Elite teams are particularly sensitive to this because champion teams seek every advantage in preparing for Olympic Games and World Cups.

Since 2008, 4 of the last 5 Olympic Champions (Men) have trained on Poligras, and at the recent 2020 Women’s World Cup 10 of the 16 teams trained on Poligras.

So, teams who choose Poligras Paris GT zero are not just helping the environment, they are giving their players the edge. Read more about why elite teams choose Poligras.

Read more about Poligras Paris GT Zero